Permanent Antistatic Solutions

A unique range of permanent antistatic additives

Immediate & Permanent Antistatic Properties

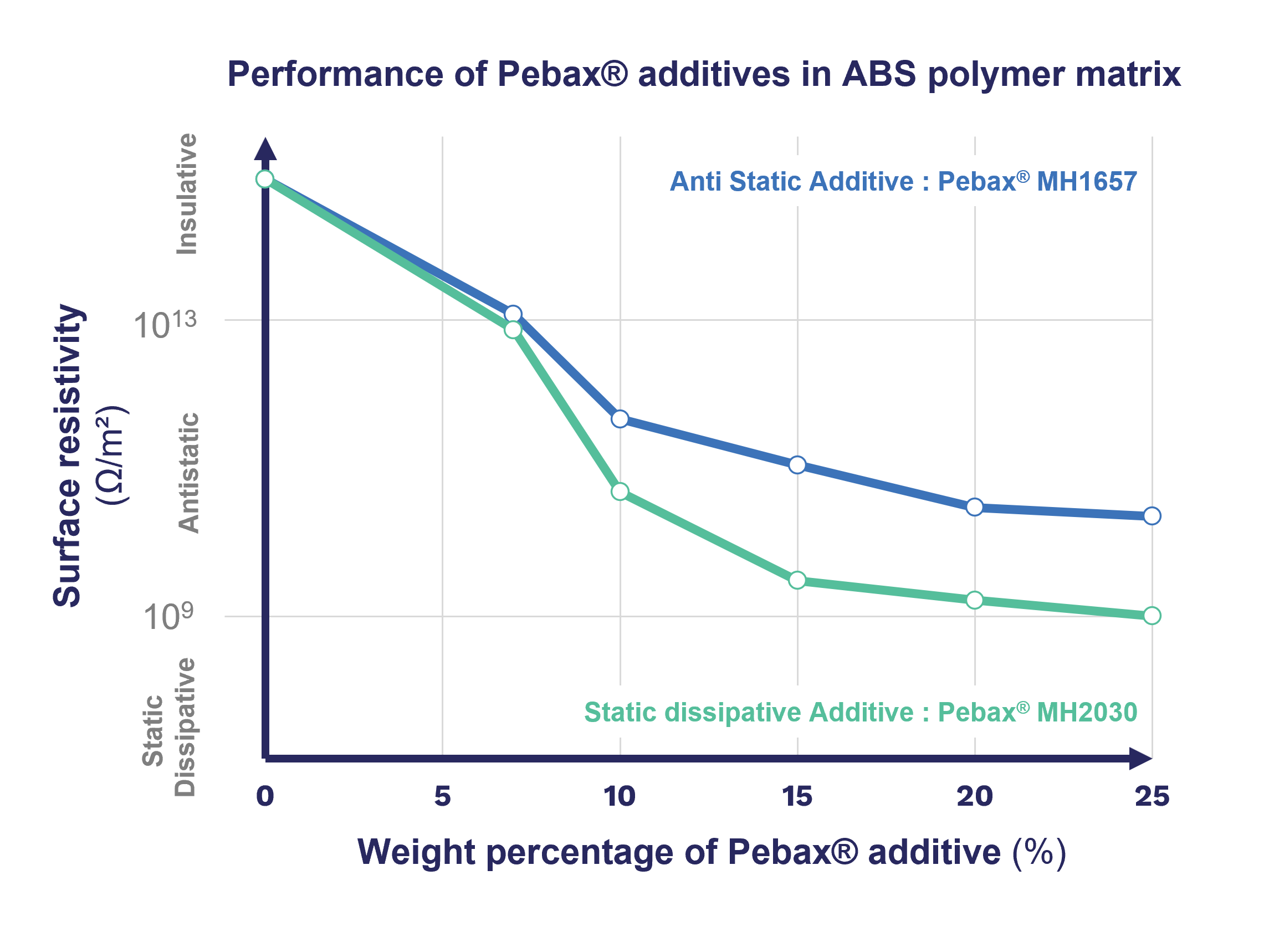

Certain Pebax® polymer grades offer a spectrum of antistatic and static-dissipative properties.

Unlike many other antistatic technologies, Pebax® antistatic polymers are permanent and non-migratory.

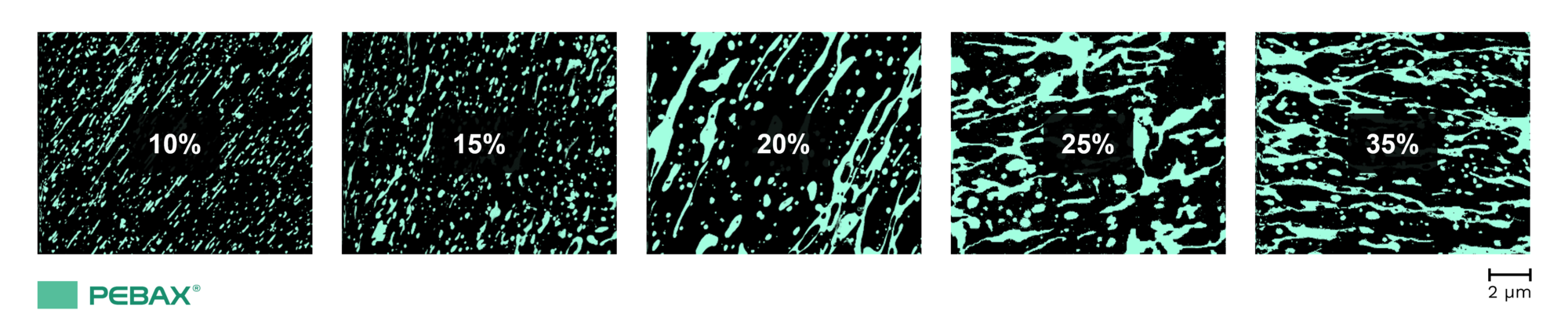

They form an immediate, continuous non-migratory 3D network within the host polymer structure. The result is an antistatic blend that is colorable (unlike carbon black solutions) and is largely independent of relative ambient humidity conditions.

Large choice of Pebax® antistatic additives

- Pebax® MV series based on PA12

- Pebax® MH series based upon PA6

- Biobased Pebax® Rnew® 30R51 SA 01 based upon PA11

Food contact and medical agreements are available for specific grades. Please contact and Arkema representative for further information.

Explore our Materials Database for technical information

Permanent antistatic additives selection by polymer matrix

Matrix with Low melting point (<180°C):

PE, PP, PMMA, POM, PC/ABS, PVC

|

Antistatic behavior: |

Static dissipative behavior: |

Pebax® MV1074

|

Pebax® MV2080

|

Pebax® 30R51

Transparent in PMMA. |

Matrix with High melting point (>180°C):

PA6, ABS, PBT, PET, PS, HIPS, PC/ABS

|

Antistatic behavior: |

Static dissipative behavior: |

Pebax® MH1657

|

Pebax® MH2030

|

Careful Control of Block Copolymer Chemistry...

For many years, Arkema has been famous for their Polyether Block Amide (PEBA) chemistry. By carefully controlling the nature of the polyether blocks (that give flexibility and tailored chemical channeling abilities) and the polyamide blocks (that give toughness and chemical resistance), Arkema offers a wide range of polymers with specific and tailored antistatic properties.

Not all Pebax® grades are antistatic in nature; only those grades whose polyether blocks are specifically chosen for their inherent ability to form continuous molecular charge diffusion channels through the matrix.

...At the Right Concentration

Even at low concentrations of Pebax® antistatic additives in the host resin, a fairly high level of static dissipation is observed.

This level increases as more additive is incorporated (compounded) until a steady-state saturation is achieved. At this critical concentration, a full and complete continuous static-dissipating molecular network has been achieved.

Morphology obtained with increasing content of Pebax® antistatic additive in a PE matrix:

A Wide Array of Processing Options...

-

Injection

- Extrusion

- Cast Film, Blown Film

- Blow Molding

...For a Wide Array of Applications

- Storage containers

- Copy machines

- Clean room anti-dust surfaces

- Medical devices

- Electronics packaging

- Electronics components

- Fibers & films

- Spray tips, nozzles

- Automotive interior surfaces

- Industrial Packaging, IBC packaging

- Food Packaging

- Consumer goods

- Cosmetic packaging