3D 프린팅용 첨단 재료

프린팅 기술별 소재 검색

With the Easy3D digital platform, you will have access to our team's powerful material recommendations to support your decision-making and part application development for on-demand manufacturing.

SIGN UP HERE

Discover 3D printing application examples with our advanced materials

Consumer products and electronics

Our Advanced Bio-Circular (ABC) materials with flagship Rilsan® PA11 are the material of choice for powder bed fusion 3D printing. 100% bio-based Rilsan® PA11 provides excellent flexibility, as well as chemical and fatigue resistance often required in consumer products and electronics applications. With our materials, we enable the creation of impossible complex designs for consumer products and electronics. Discover some of the recent applications with our materials including cosmetics packaging, eyewear and electronic devices. CHECK OUT THE CONSUMER PRODUCTS APPLICATION EXAMPLES

Industrial applications

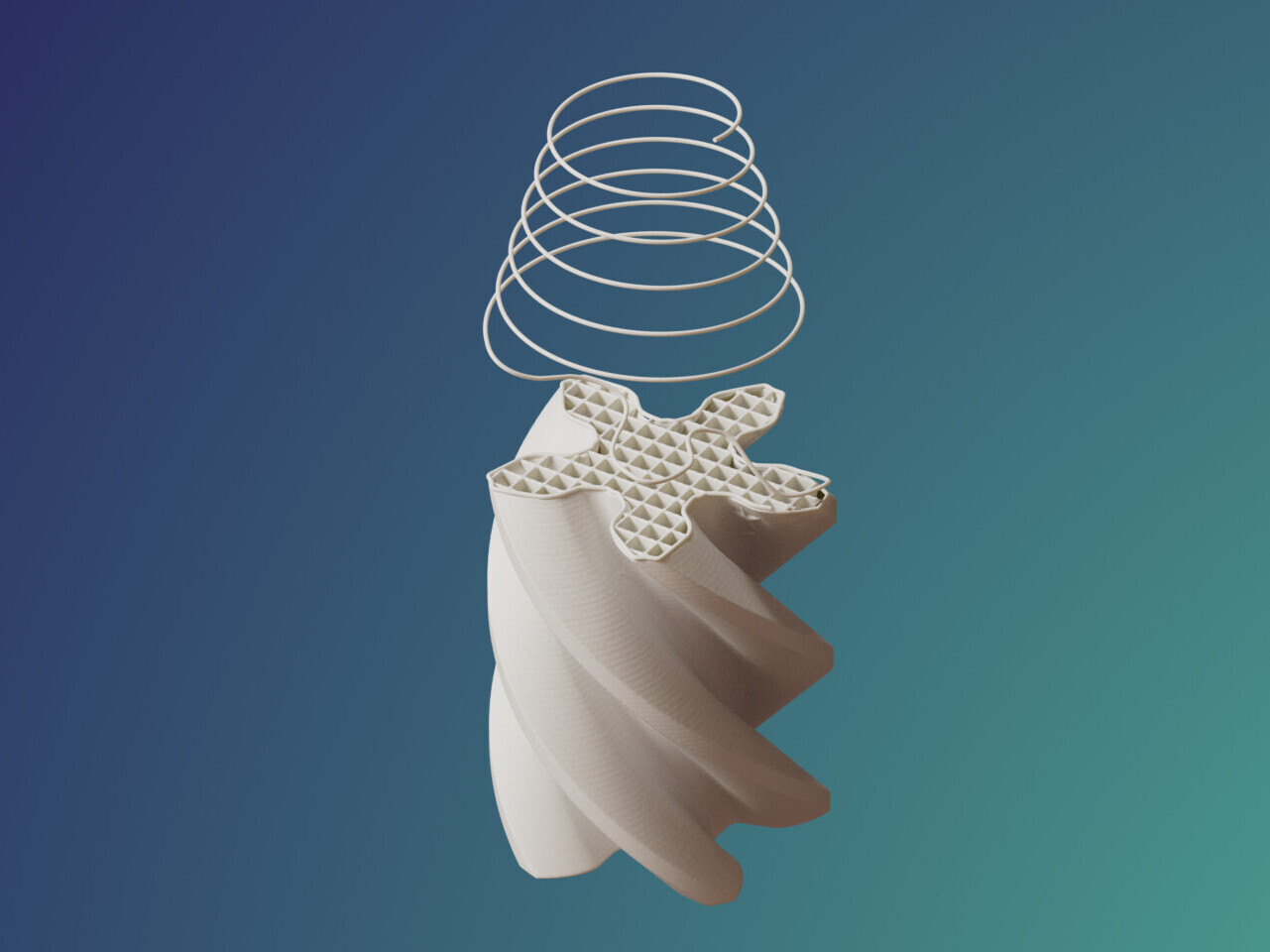

Industrial applications in 3D printing often are highly demanding in terms of material performance. Our Rilsan® PA11, Kynar® PVDF and Ultra-high-performance Kepstan® PEKK enable 3D printing of industrial pieces with the most demanding requirements such as low water absorption, low flammability as well as fatigue and impact resistance. Today our lightweight materials are used for printing industrial pieces such as bearing cages, pico turbines, pipe fittings and embankment rollers as replacement of metal parts and stockshape. The combination of advanced material performance with additive manufacturing promise to disrupt the supply chain in the industrial segment. CHECK OUT THE INDUSTRIAL APPLICATION EXAMPLES

Healthcare applications

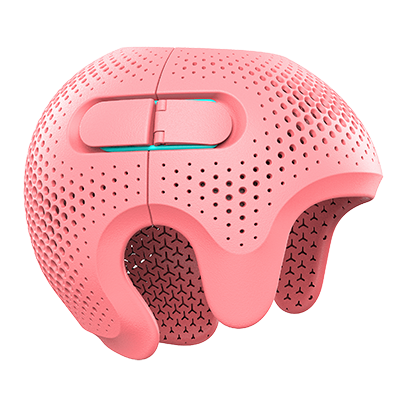

Rilsan® Polyamide 11 is the material of choice for medical device applications such as orthotics and prosthetics that require open customization. Thanks to the material's flexibility, 3D-printed devices for orthotics provide a high level of comfort to patients. Also, 3D printed devices with Rilsan® Polyamide 11 are resistant to impact, and chemicals related to sweating and are easy to clean. Therefore our customers choose 100% bio-based Rilsan® Polyamide 11 for application as ankle-foot orthosis, orthopedic insoles and cranial orthosis. CHECK OUT THE MEDICAL DEVICES APPLICATION EXAMPLES

3D-printed objects in sports

The sports industry is one of the early adopters of 3D printing technology and today we can find devices and accessories entirely or partially 3d printed with high-performance materials. Our materials are adapted to creating complex but lightweight lattice shapes and custom-made pieces while guaranteeing the material performance of the 3D-printed pieces. Some examples of 3D printing applications of our materials are ski boots, helmets, golf club and others. CHECK OUT THE SPORTS APPLICATION EXAMPLES

Automotive &

Transportation

Find out more in the Resources section

Check out our latest case studies, white papers and articles prepared by our additive manufacturing experts.

GO TO THE 3D PRINTING RESOURCES

3D 프린팅 서비스

당사의 팀은 고객에게 최상의 서비스를 제공하기 위해 최선을 다하고 있으며, 여기에는 파트너와 협력하여 설계, 시뮬레이션, 프린팅 및 후처리 단계에서 고객의 모든 요구를 충족할 수 있도록 보장하는 것이 포함됩니다.

See what our customers are saying

AON3D

KIMYA PEKK-A filament, made from Arkema's Kepstan® PEKK, is a PAEK family material with exceptional mechanical, thermal, and chemical resistance properties. Kepstan® PEKK is optimized for easier 3D printing and better interlayer adhesion. In this timelapse, a Kepstan® PEKK fluid mixer was printed on the AON M2 with a section cut out to see the inner workings.

Founded in 2015 by a team of materials engineers, AON3D is a Montreal-based additive manufacturing hardware, software, and material science company. AON3D’s large high-temperature AON M2+ industrial 3D printer with Arkema Kepstan® PEKK enables engineers and designers to easily create complex parts with superior mechanical and thermal properties.