Breathable Films

High-Performance Monolithic & Breathable films

Certain Pebax® polymer grades are inherently breathable when extruded alone or in combination with otherwise non-breathable resins.

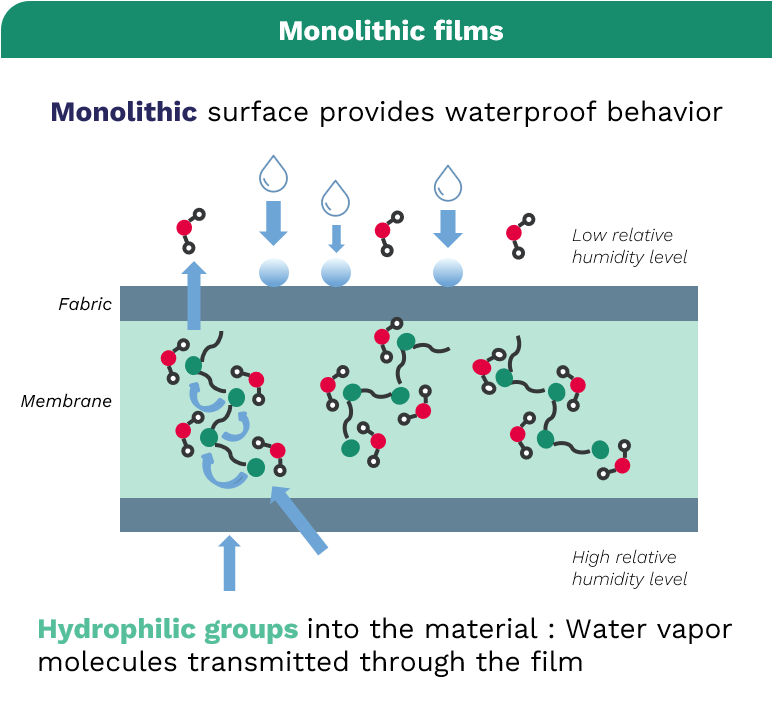

Through very careful choice of proprietary polyether block chemistry within the Pebax® polymer backbone, a continuous molecular channel may be achieved that allows physical transport of water vapor molecules while simultaneously blocking any transport of liquid water.

ADVANTAGES OF PEBAX® BREATHABLE FILMS

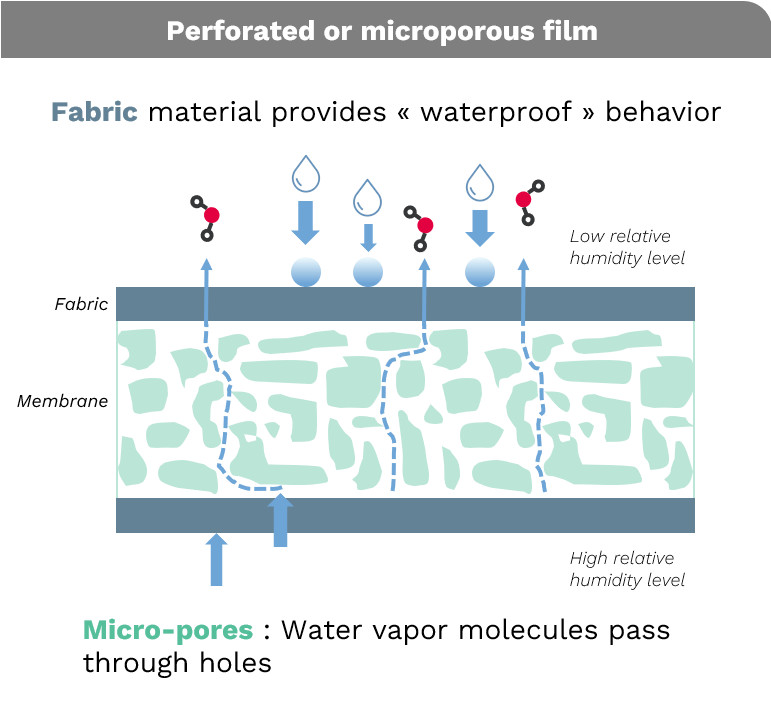

Unlike perforated or microporous films, monolithic films made from Pebax® polymers do not rely on vapor transport through holes or voids (which enables physical transport in both directions).Advantages of monolithic films include:

- Adjustable Moisture Vaport Transmission Rate (MVTR)

- No loss of performance over time (no plugging)

- Good tear resistance

- Excellent virus, liquid & odor barrier

- High water entry pressure

- Free of fluorinated additives

Watch the webinar recording:

Breathable membranes uses by market:

Selecting the right grade:

A COMPLETE PRODUCT OFFERING

There are four grades of Pebax® materials offered for breathable/hydrophilic applications:

- Pebax® 30R51: Bio-based grade with high breathability

- Pebax® MH 1657: Higher melt point, Best in class for solvant cast process

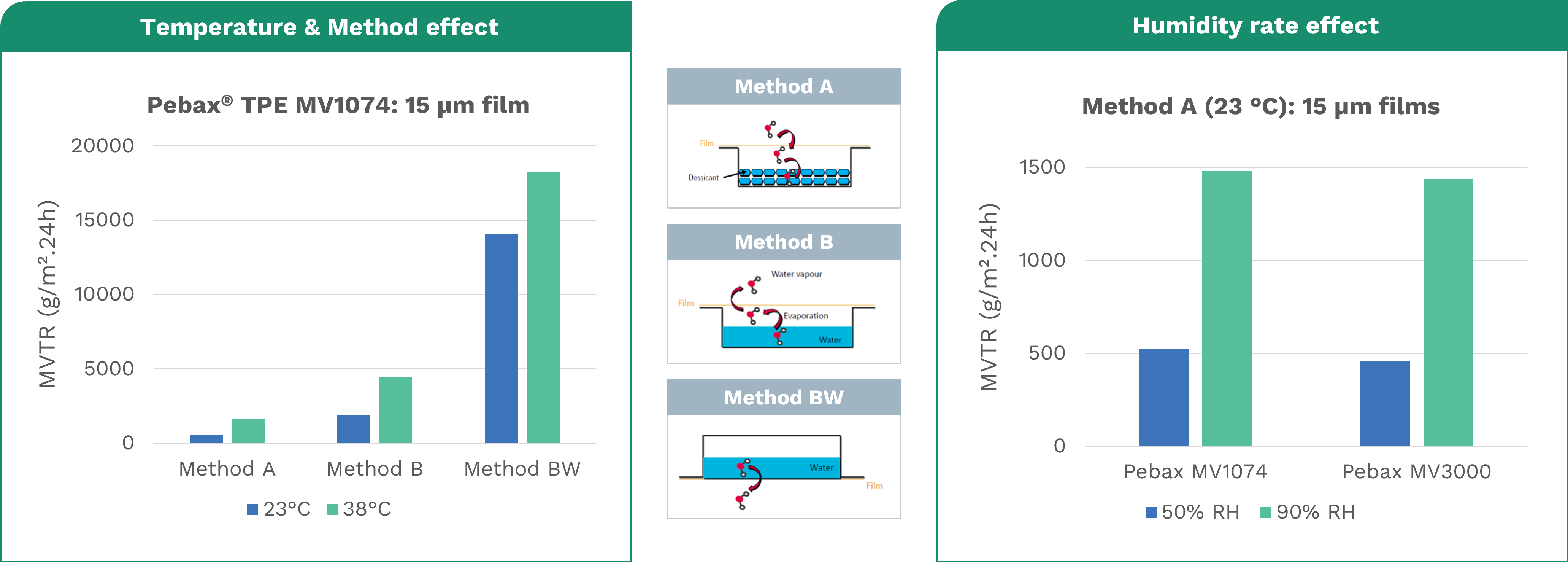

- Pebax® MV 1074: Standard grade with high breathability

- Pebax® MV 3000: Soft touch, Ease of processing, Good adhesion on different substrates by extrusion coating

Each grade is tailored in its performance according to the careful selection by Arkema of the polyether and polyamide blocks in the Pebax® polymer backbone.

Check Technical Datasheets on our Materials Database !

TUNING BREATHABLE PERFORMANCE

Permeability performances are also sensitive to environmental conditions:- Temperature

- Humidity

FOCUS ON: BIO-BASED PERFORMANCE

Pebax® Rnew® 30R51 is 45% bio-based derived from a renewable feedstock: castor beans.

This grade allows an even better permeability with a 30% increase in MVTR compared to the rest of the range.

Looking for technical data?

Search for technical data sheets and even compare grades side-by-side