Food and Beverage Processing

Focus On: Kynar® PVDF

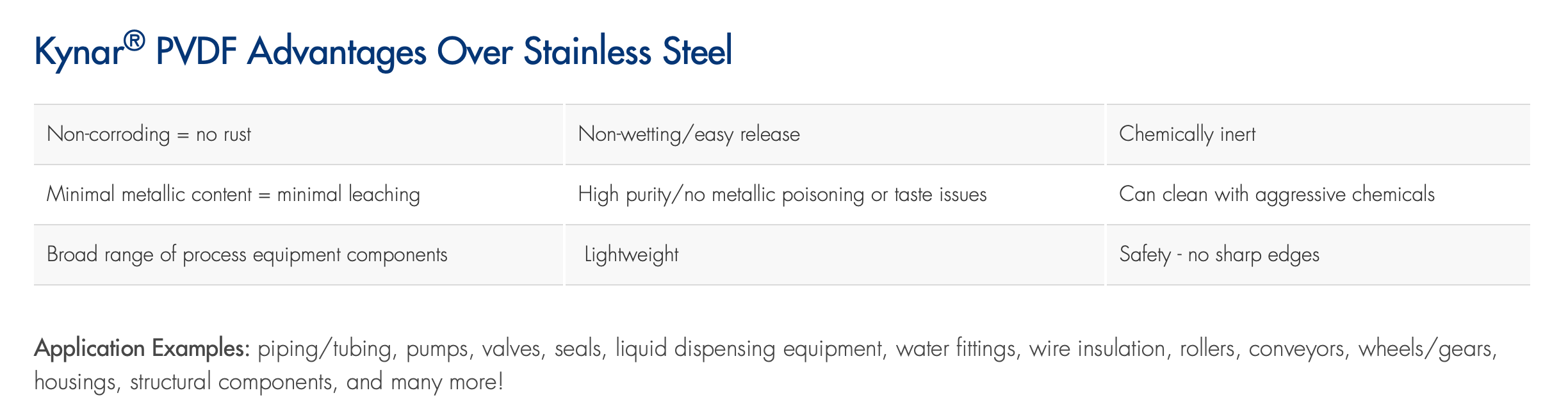

When your food and beverage processing calls for high temperature capability and extreme chemical resistance, while still maintaining mechanical strength and regulatory compliance, certain grades of Kynar® resins are an ideal solution.

Industry Specification Conformity

Certain grades of Kynar® and Kynar Flex® resins conform to specifications and requirements for the food processing industry, including FDA 177.2510 and 177.2600 for Repeated Contact with Food, CRC Kosher, NSF 51 & 61, and USP Class 6. Kynar Flex® can be combined with polyurethanes and other structural polymers to form very flexible tubes for beverage processing. An inner layer of Kynar Flex® resin provides excellent chemical resistance and a low propensity to absorb flavors from previous beverage exposure.

Chemical Resistance

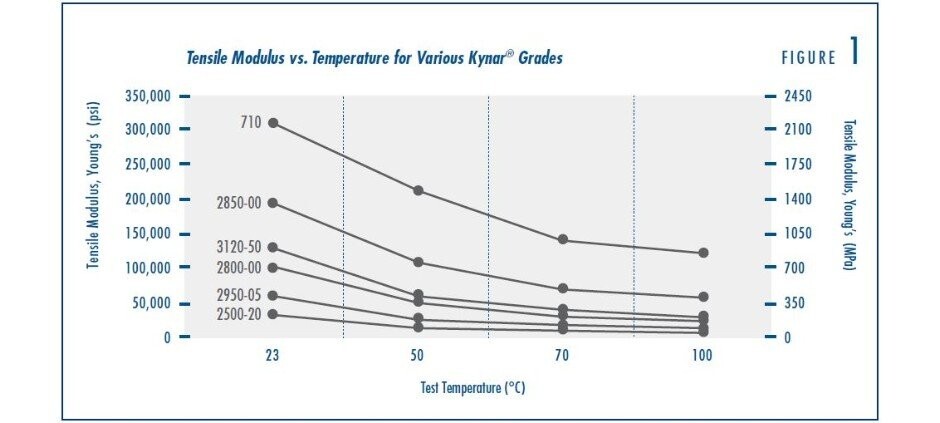

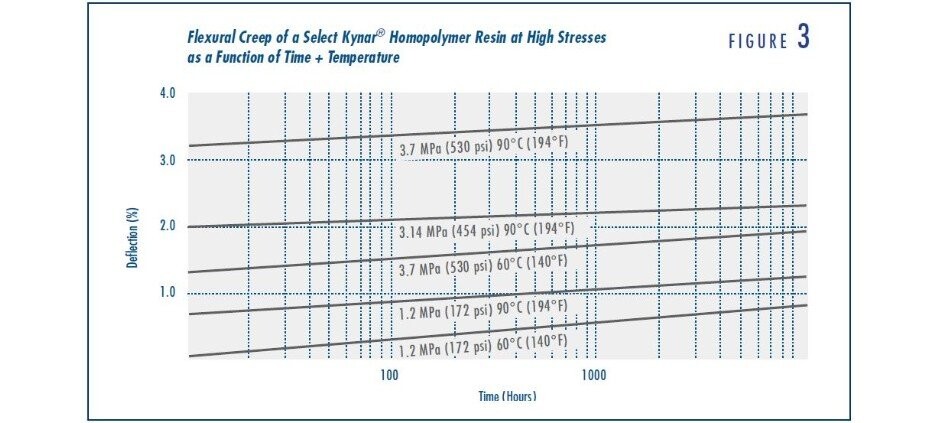

Kynar® PVDF pipes, pumps, tubing and tanks stand up to many cycles of chlorinated cleaning agents, peroxides, acids, soaps, and hot steam cleaning to 30 psi. Pipe and tubing systems in many diameters are available as mechanically joined, threaded, or fusion welded. The flexibility of Kynar® PVDF and Kynar Flex® PVDF can be varied without the use of additives to meet the needs for rigid systems or flexible hoses and tubes.

Applications in Food Processing

- Beer

- Wine and other alcoholic beverages

- Fruit juices

- Dairy products

- Meat and poultry

- Soft drink dispensers

- Coffee dispensers

- Hot sauces and condiments

Kynar® resins can be fused together to any other grade of Kynar® resins in various methods allowing you to have a complete solution for your processing needs.

Focus On: Rilsan® Resins

Produced from castor oil, Rilsan® PA11 is a high-performance polymer of 100% renewable origin. Rilsan® PA11 has been a trusted source of performance in highly demanding applications for over 70 years.

Beverage Dispensing

The inert nature of Rilsan® PA11 allow it to be used safely and efficiently in the beverage market. Rilsan® PA11 has characteristics which work for Beer and Soda dispensing:

- Low permeation - Taste of beverage is not affected

- Low extractables - No contamination of beverages

- Chemical resistance - Easy to clean and maintain

Food Processing

Rilsan® PA11 and Pebax® grades can be used for food processing belts and bumpers because of their unique characteristics:

- Light weight - Allows for longer belts

- Flexible - Maintain flexibility at low and high temperatures

- Inert to most chemicals - Easy to clean and maintain

- Durable - Have lasting power for cost efficiency

- Low creep - Maintains its structural integrity

Rilsan® PA11 Applications

The unique chemical inertness of Rilsan® PA11 makes it ideal for many different applications:

- Food Contact Appliances - Rilsan® Clear G170 (Datasheet US/SI) and Rilsan® Clear G850 Rnew (Datasheet US/SI) are certified food contact approved grades by NSF/ANSI 51 making them ideal for consumer appliances such as coffee makers and microwaves.

- Candy Trays - Excellent cold impact performance (-40°C) means trays can take abuse

- Food Display Trays - Can be steamed and/or microwaved while staying transparent

- Cheese/Bread Boxes - Paired with Arkema breathable membranes, can keep food fresh and flavorful

- Other - Contact an Arkema technical representative today to discuss how Rilsan® PA11 can be used for your food and beverage processing needs.

Orgalloy® Polyamide Alloys

Orgalloy® grades are proprietary compatibilized alloys of PA6 and functionalized polyolefins. They are designed to offer improved dimensional stability, lower density and better mechanical properties than PA6 and PA66 resins. Their important chemical and physical properties combined with economic and process advantages allow them to be used in a variety of ways in the Food & Beverage market.

Focus On: Coatings for Metal Protection

Rilsan® Fine Powders

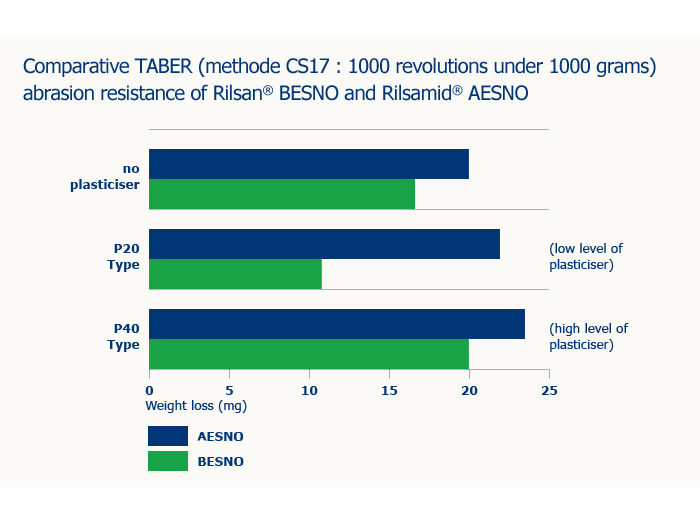

Using Rilsan® Fine Powders as a coating in food processing will extend the life of your equipment promoting cost effective manufacturing.

Rilsan® Fine Powders are applied to metal applications such as dough mixing hooks, processing bowls, and beverage dispensing machines making the equipment corrosion resistant.

If you have equipment which is subject to abrasion, scratching, corrosion or harsh cleaning agents, Rilsan® Fine Powders have excellent characteristics for the job at hand.

Industry Specification Conformity

Certain grades of Rilsan® have current industry approvals, while most others can conform to requirements.

Current Full FDA Approval:

- Rilsan® T NAT 2P (natural fluid-bed grade)

- Rilsan® NATURAL ES (natural electrostatic grade – this has a semi-translucent finish)

- Rilsan® 7050 White FB (white fluid-bed grade)

NSF61 Approval:

- Rilsan® 7443 Blue MAC FB

- Rilsan® 7450 Black AC FB

- Rilsan® 5161 Grey MAC FB

- Rilsan® 1464 White EC ES

- Download the Food and Beverage Market Presentation

- Download the Conveyor Belts for Food Processing Leaflet

- Download the Beverage Processing with Kynar® PVDF Leaflet

- Download the Kynar® and Kynar Flex® PVDF Performance Characteristics and Data Brochure

- Download the Kynar Flex® PVDF: Superior Permeation Barriers Brochure

- Download the Kynar® PVDF Chemical Resistance Brochure

- Download the Rilsan® PA11 Product Family Presentation

Looking for technical data?

Search for technical data sheets and even compare grades side-by-side