Thermoplastic pellets for filament extrusion

Kepstan® PEKK for filament extrusion

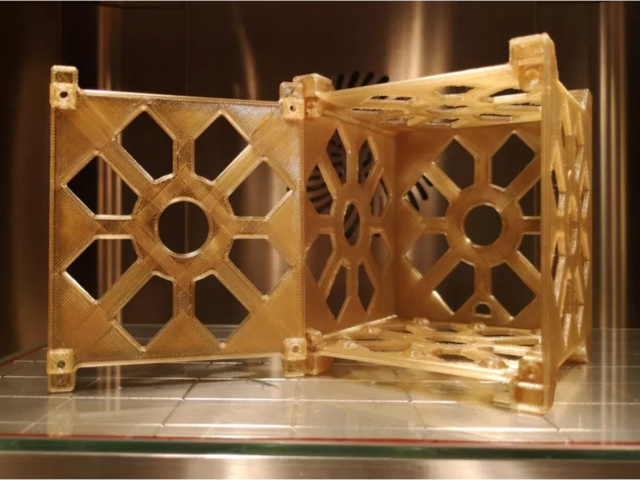

Kepstan® PEKK (PolyEtherKetoneKetone) is the latest addition to the PAEK (Poly-Aryl-Ether-Ketone) family, and is ideally suited for metal replacement thanks to its very high service temperature, chemical resistance, and excellent fire retardancy.

Download Kepstan® PEKK for Fused Filament Fabrication Brochure

Key benefits

The material of choice for metal replacement

-

Outstanding high temperature performance

-

Inherent flame resistance, low smoke generation, and toxicity

-

Excellent chemical resistance

-

Outstanding mechanical, wear, and impact properties

-

High dielectric strength and good insulating properties

-

Easier to print than PEEK - minimal part warping

-

Possible to produce either amorphous or semi-crystalline parts

Kynar® PVDF for filament extrusion

Kynar® PVDF (polyvinylidene fluoride) resins are extremely resistant to harsh chemicals and UV radiation. They are known to be among the most durable polymers in the world. This tough semi-crystalline fluoropolymer, formulated for printability, benefits from outstanding Z-direction strength and ductility. Filaments made from Kynar® resins are particularly suited for early-stage prototyping or short-run manufacturing. Kynar® fluoropolymers are specified for printing chemical processing equipment, fluid transport parts, outdoor exposed elements, or jigs & fixtures.

Download Kynar® PVDF for Fused Filament Fabrication Brochure

We are thrilled to announce 3D-printed bridge made with our recycled Kynar® PVDF by SparcBridge.

The estimated lifespan of this bridge is 20 to 30 years longer than alternative polymers!

Key benefits

Material of choice for the chemical industry

-

Cost effective compared to subtractive

-

Continuous use temperature up to 130°C

-

Excellent resistance to a broad range of chemicals

-

Non-hygroscopic: no drying of filament or special storage needed

-

Inherently UV-resistant for exterior applications

-

Very good abrasion resistance

-

Low smoke and flame characteristics

-

Long-term hydrolytic stability

Pebax® elastomers for filament extrusion

Pebax® TPA (elastomers) are an incredibly versatile range of materials. They are extremely lightweight, flexible, fatigue resistant, impact resistant, and exhibit unmatched energy return compared to alternative materials like TPU.

Download Pebax® Elastomers for Fused Filament Fabrication Brochure

Key benefits

Excellent processing characteristics

Low energy loss factor across wide temperature range

Low density

Very good layer adhesion and elongation at break

High impact resistance, especially at low temperature

Partially bio-based grades available